Rooms for Energy Technology Students

Energy technology students can book lab facilities on the Main Campus as part of their studies from Monday 25.8.2025 onwards from Peppi. Labs can also be booked using the QR codes on the doors, or booked directly from Tuudo.

Students book the facilities through the Facility reservations button on the Peppi front page. More detailed instructions for students on how to book facilities can be found here.

The DP39.1 laboratory is divided into several bookable sections, and students can book these rooms during campus opening hours for hour-long periods when the rooms are free:

- R35DP39.1Höyry Höyryprosessi (Steam Process)

- R35DP39.1Pumppaus Pumppausmoduuli (Pumping Module)

- R35DP39.1Valmet ValmetDNA

- R35DP39.1Vesi Painevesimoduuli (Pressurized Water Module)

- R35DP39.1RTKO07 RTKO-DP38-07 (Tietokone) (PC)

- R35DP39.1RTKO08 RTKO-DP38-08 (Tietokone) (PC)

- R35DP39.1RTKO09 RTKO-DP38-09 (Tietokone) (PC)

- R35DP39.1RTKO10 RTKO-DP38-10 (Tietokone) (PC)

You can find the rooms by typing R35DP39.1 in the Rooms section.

Students can also book room R35DP66A Automaatiolaboratorio OR – A-osa vesiprosessi (waterprocess) and R35DP66B OR – B-osa Muut laitteistot (other devices) on weekdays during campus opening hours for two hour-long periods when the room is free.

Safety regulations and operating practices of the Energy Technology Laboratory

Laboratory equipment may not be used by anyone without familiarity with and understanding of these instructions.

The equipment of the Energy Technology Laboratory is such that it can lead to dangerous situations if it is misused. It can cause damage to both people and the equipment itself. To make the environment safe and comfortable, everyone should follow these simple and easy rules. Neglecting the rules and ignoring them will lead to case-specific sanctions, such as disqualification from the course.

The room has junction boxes with a voltage of 400 VAC. Do not open any enclosure that does not have the letters JB (Junction Box) in the symbol. No connections may be dismantled or any modifications made to them unless specifically specified in the work instructions or the supervisor. If such work is involved, special care must be taken to ensure that the connections are restored after the work has been completed. Each module can be de-energized by removing the plug of the module in question from the socket (16A, 3-phase).

Hot surfaces may occur in the equipment. In the event of a burn, the first aid is rinsing with cold. The nearest water points are located in the toilets on the other side of the corridor and in the chemical laboratory (emergency shower).

Emergency Exit

In an emergency, the facility must be exited along the route marked with signs on the doors. The electric lock is opened in an emergency by pressing the button next to the door as shown in the picture

Before the operation

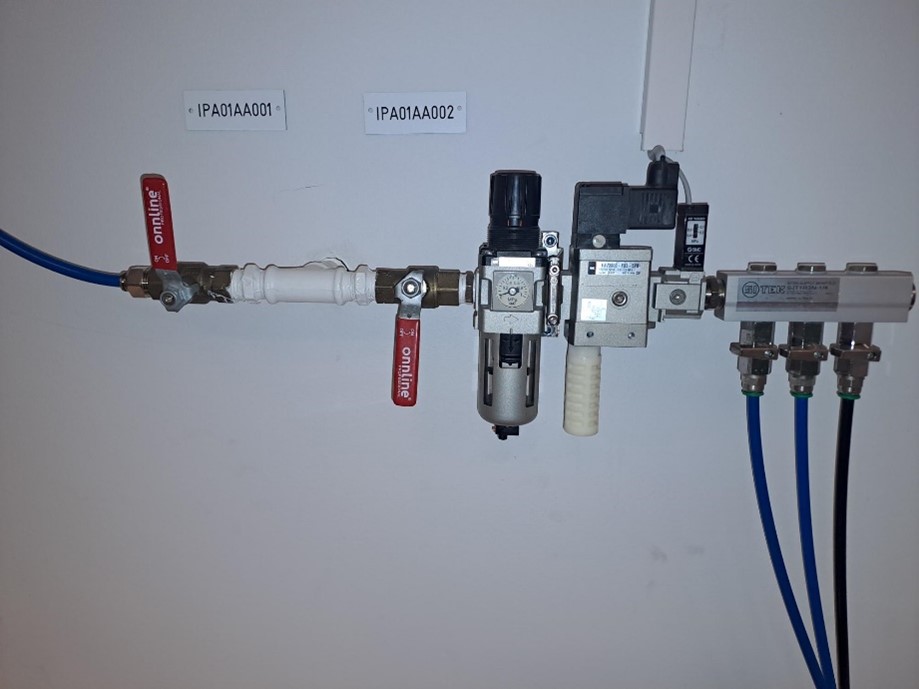

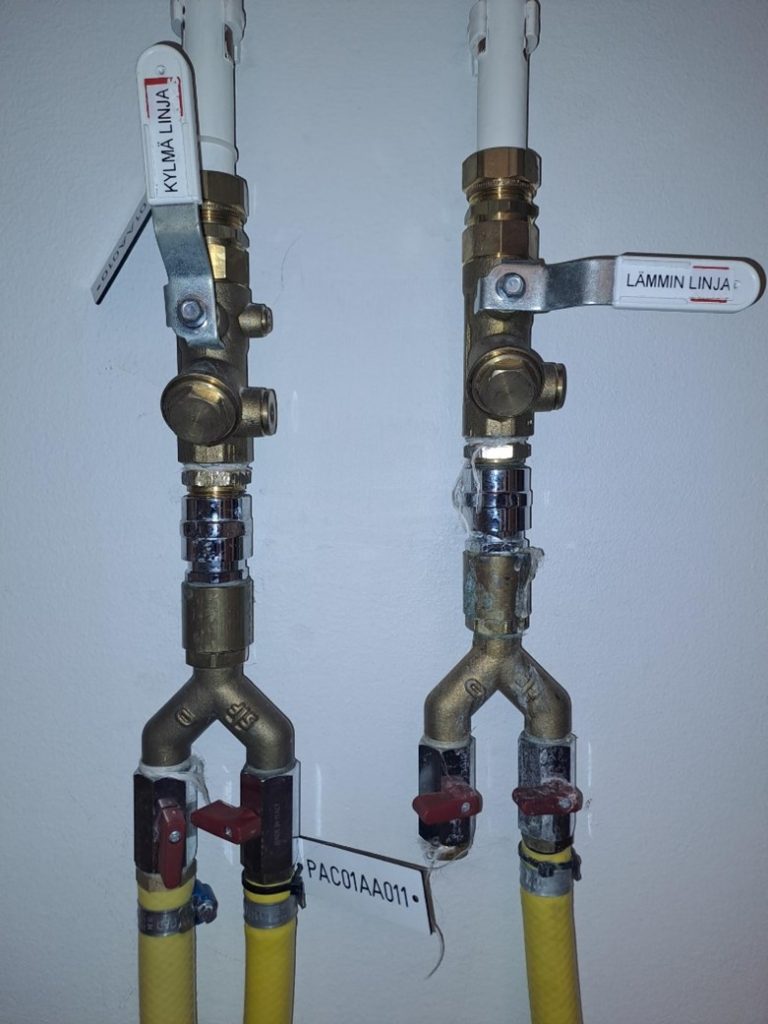

Find out for yourself how to cut off the compressed air, water and electricity in the system.

Do not operate the hardware in any way until you have determined how that operation will affect the process. With incorrect operation, e.g. damage equipment and cause water or personal injury.

During operation

Everyone is responsible for their own actions. If someone asks you to e.g. When you open the valve, you are responsible for what happens at that time. If you don’t know in advance whether something can be done safely, don’t do it until you are aware of it.

When water is run into the sewer, it must be ensured that all the water actually goes into the sewer. This should be monitored while driving, and especially at the beginning of sewer runs, it should be checked that water does not go anywhere else.

When operating the steam module locally, protective gloves must be worn. In addition, protective goggles must be worn when blowing out and sampling.

After the operation

- Make sure that all the valves you operate eventually return to the same original position.

- Make sure that all the engines you operate have actually stopped when the work stops. This is not self-evident if changes have been made to the firmware software. Even putting logic to a stop does not necessarily stop a running pump. So make sure by watching and listening that the engines have actually stopped.

- When you finish working, make sure that the valves on the wall are closed (water and air are turned off). The electricity must always be on during the process.

- Make sure that the workstation remains in a tidy condition. Of course, all the items you use will be returned to their original places.

- When you leave the room, turn off the lights last.

I have read and understood the above instructions. By making a reservation I confirm that I follow these rules and instructions.